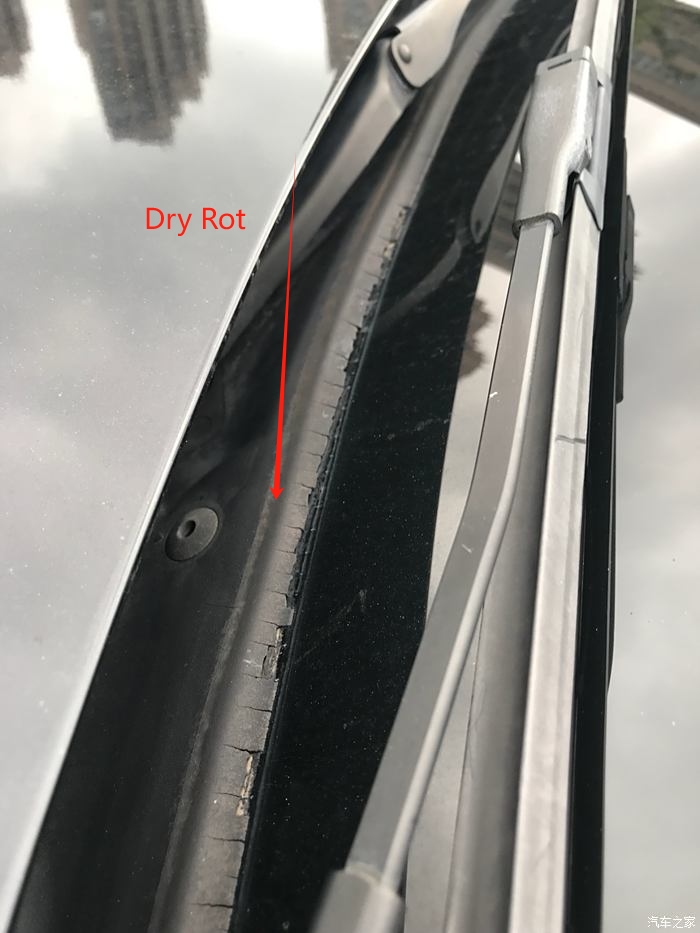

Indeed, rubber doesn’t last forever. Over time, it degrades and wears out. In terrible conditions, it may crack or snap. This aging sometimes looks like rot, so people named it Rubber Dry Rot.

Have you ever replaced an old rubber seal strip on a door or window? The windows or doors may not have been used for a long time, but they are worn or cracked. They are no longer as flexible as they used to be and break easily with a slight bend. This is basically called dry rot.

In this article, we will discuss this topic briefly. You will learn why or how rubber dry rot happens and how to protect your rubber seal. We will also discuss other problems with rubber. This guide will help most home or car owners. Those involved in the rubber seal strip business will also benefit from this.

Does Rubber Rot? What is Rubber Dry Rot?

Rubber dry rot doesn’t mean the actual rot we see on organic materials. Generally, fungi decompose the organic matter and produce rot. In the case of rubber seal strips, fungi can not decompose the material, so rubber doesn’t rot. However, the name “Rubber dry rot” originally comes from the dry, worn-out condition of the rubber.

Rubber is a very durable material. People often prefer rubber over plastics because it is flexible, elastic, and resistant to wear. Synthetic rubber is made through various chemical processes, so rotting is impossible. When a rubber seal strip wears out, it loses its flexibility and breaks with a slight bend. You may sometimes observe cracking, flaking, or completely drying.

What Causes Rubber Dry Rot?

Rubber dry rot is a type of rubber deterioration problem that may happen due to several factors. You must know these factors to take the necessary steps for your rubber products.

Rubber Seal Strips Age

One of the most common reasons rubber seal strips deteriorate is their age. Every rubber product has its prescribed lifespan. As you know, rubber materials degrade over time. When they reach their lifespan, they show symptoms of deterioration. If you still use the rubber seal strips, it shows dry rot.

You can not stop this natural aging process. However, you can slow it down by preventing heat, moisture, or UV radiation.

High or Low Temperature

Temperature is one of the most crucial factors to consider. Every rubber weather stripping has a specific temperature rating. For instance, EPDM can remain stable from -50°C to +150°C (-50F to 302F). High heat can degrade your rubber seal strip if the working temperature exceeds this range.

What happens when the temperature goes beyond the limit? It typically softens the rubber. Then, the high heat gradually deforms the rubber’s shape. When it happens a number of times, the cracking appears.

Exposure to UV Radiation

The sun is the primary UV light source, particularly damaging rubber products. It breaks down the molecular forms of rubber compounds, called photodegradation. Because of this, the rubber seal strip loses its flexibility and strength, eventually leading to cracks.

As time passes, these cracks penetrate deeper into the material. Later, you can see the dry rot on rubber seal strips. FYI: UV rays can be made through various ways. It is not just limited to sunlight. Therefore, you must check where your place is free from UV radiation.

Unfavorable Weather Conditions

Rubber seal strips are often used outdoors. They frequently face varying weather conditions. Sometimes, they face heavy rain, while sometimes, they face high snow. Wind and humidity are regular cases. As you already know, extreme temperature is one of the main reasons for dry rot on rubber materials.

Besides, moisture in the air can cause the rubber to sell and shrink as it dries. In this way, the cracks are formed. On the other hand, wind can also carry dust or other particles. These weather conditions can lead to dry rot on rubber weather stripping as time passes.

Lack of use and Inaccurate Storage

This is an interesting reason why most rubber weather stripping shows dry rot. When the rubber is not used regularly, it can lose flexibility and become stiff.

Additionally, inappropriate storage can also create rubber dry rot. Once again, if your storage facility involves high heat, moisture, or UV exposure, the rubber will quickly form dry rot. Therefore, you must find the best solution to store rubber seal strips. In this case, you can seek professional assistance at Seashore Rubber Customer Point.

Tips on How to Prevent Dry Rot in Stored Rubber Weather Stripping

You can now realize the seriousness of the rubber dry rot problem. Also, recovering once dry rot happens on the rubber is nearly impossible. So, you can take the necessary steps before this problem shows up.

Pointer #1 Keep It Away From Direct Sunlight And Keep It Cool

Sunlight is one of the main culprits in rubber drying out. UV rays break down the rubber’s structure and cause it to crack. To prevent this, you must choose a place away from direct sunlight. Try to avoid areas near windows or doors. You can cover the storage box to maintain a dark environment.

Pointer #2 Before Storing, Keep It Cool and Store It in A Dry Place

Before storing, make sure the rubber weatherstripping is cool. As you know, heat can accelerate the aging process. Moisture can cause the rubber to swell, weakening its performance. Both heat and humidity make the rubber more likely to dry rot. You must ensure proper ventilation in the storage facility.

Pointer #3 Try to Ensure a Consistent Temperature

Once again, heat can quickly deteriorate your rubber seal strip. Sudden temperature changes also cause the rubber to expand and contract. To prevent this, you can focus on controlling the temperature in the storage facility. In major hot/cold countries, you must avoid a place that experiences extreme heat or cold weather.

Pointer #4 Use an Airtight Bag to Store Rubber Seal Strips

When storing the rubber seal strip, you could use an airtight bag. An airtight bag can protect your rubber seals from air, moisture, and dust exposure. This simple step can eliminate the need to use rubber protectants.

Pointer #5 Use Rubber Protectants

If you want more protection, you could also apply a rubber protectant. However, people prefer rubber protectants for ongoing rubber usage.

Rubber protectants mainly create a light coating that prevents dry rot. It also keeps your rubber seal in good condition for future use.

Other Rubber Problems

Other than dry rot problems, you may also find other rubber problems. The causes or reasons for these problems are the same as for dry rot problems. Even the preventions are the same.

(1) Aging, environmental exposure, or chemical reactions create surface or deep cracks.

(2) UV exposure, pollutants, or chemicals cause the rubber to fade, yellow, or stain.

(3) Cold temperatures cause the rubber to stiffen or harden, reducing flexibility.

(4) Moisture causes the rubber to swell, or drying brings back shrinkage,

(5) High heat, pressure, or inaccurate storage causes rubber surface deformation. Due to these environmental factors, you may observe warping, blistering, or bubbling.

(6) The breakdown of rubber compounds may produce a sticky texture on the rubber surface.

(7) Continuous friction causes rubber seal pitting or erosion.

(8) Sometimes, you may observe some whitish, powdery dust on the rubber seal strips. This happens because the waxes or other additives have migrated to the surface.

Frequently Asked Question

Is Fixing Dry Rot On Rubber Seal Strips Possible?

No, fixing dry rot on rubber seal strips is nearly impossible. Dry rot occurs when a rubber weather stripping loses its flexibility. Also, when a rubber becomes fragile, you can’t restore its original properties. However, you can take the necessary steps to prevent dry rot. Regular maintenance and proper use of rubber seal strips can protect rubber from dry rotting.

How Long Does It Take For Rubber To Dry Rot?

The exact time typically depends on different types of rubber. Some rubbers are ideal for outdoor use, while some are for indoor use. Rubber exposure to UV resistance, ozone, or temperature for a long time starts drying out.

For example, natural rubber may start showing rubber dry rot in 3-5 years, while EPDM is ideal for outdoor uses and can last more than 20 years. Other types of rubber generally dry out in 5-6 years.

Is 100% Rubber Biodegradable?

Natural rubber is 100% biodegradable. As you know, it comes from the latex of rubber trees. Although the biodegradation process is very slow, it may take several months to years. However, synthetic rubbers are not biodegradable. They are made from petrochemicals through the vulcanization process.

Why Can’t Rubber Be Recycled?

Rubber recycling is challenging due to its chemical structure. You can not just melt it and reuse it for other products. Most rubbers are made through a vulcanization process, which creates cross-links between polymers.

Summary

Dry rot is not an actual rot we see on biological matter. Even rubber trees may rot, but not the rubber itself. Due to various factors, rubber seal strips wear out and lose flexibility. When you bend them slightly, they break easily. This type of situation is often called rubber dry rot.

To prevent rubber dry rot during storage, you must take the necessary steps. Ensure the storage facility is well-ventilated and free from heat, moisture, and UV radiation. You could also use airtight bags or rubber protectants.